-

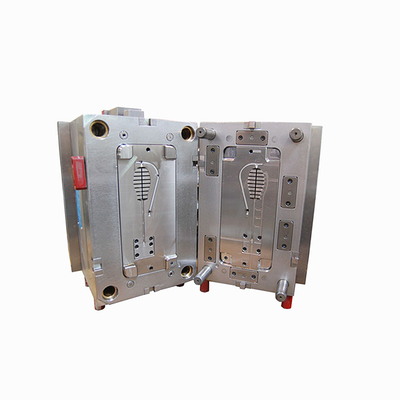

Automotive Injection Molding

-

Precision Injection Molding

-

Plastic Injection Molds

-

Hot Runner Injection Mould

-

Cold Runner Injection Molding

-

Double Injection Mold

-

Single Cavity Injection Mold

-

Plastic Blow Mold

-

Custom Injection Mold

-

Phone Case Molds

-

Insert Injection Molding

-

Die Casting Mould

-

Multi Cavity Injection Molding

-

Commodity Mould

-

CNC Machining Parts

| Cavity | Multi-Cavity | Color | Customized |

|---|---|---|---|

| Lead Time | 15-30 Days | Surface Finish | Smooth |

| Application | Automotive | Package | Carton/Wooden Case |

| Transportation | By Sea/Air/Express | Molding Type | Injection Molding |

Product Description:

Automotive Injection Molding is a type of injection molding that is used for the production of car parts. It is a highly efficient and cost-effective method of manufacturing automotive parts that enables greater precision and accuracy in the finished product. Automotive Injection Molding utilizes customized designs and high-quality materials to ensure that the parts produced are of the highest quality. The parts are then shipped in either Carton or Wooden Cases, and can be transported via Sea, Air or Express shipping methods. Automotive Injection Molding provides a reliable and efficient way to manufacture car parts, making it an ideal solution for vehicle manufacturers. With its customizable design and efficient shipping options, Automotive Injection Molding is the perfect choice for vehicle parts production.

Features:

- Product Name: Automotive Injection Molding

- Molding Type: Injection Molding

- Color: Customized

- Application: Automotive

- Transportation: By Sea/Air/Express

- Product Size: Customized

Technical Parameters:

| Parameter | Value |

|---|---|

| Product Size | Customized |

| Transportation | By Sea/Air/Express |

| Color | Customized |

| Cavity | Multi-Cavity |

| Molding Type | Automotive Injection Molding |

| Tolerance | ±0.02mm |

| Lead Time | 15-30 Days |

| Surface Finish | Smooth |

| Material | Plastic |

| Mold Life | 500,000-1,000,000 Shots |

Applications:

Automotive injection molding is a process that is used to manufacture high-quality automotive components with a smooth surface finish, multi-cavity design, and high-precision tolerance of ±0.02mm. This process is essential for making automotive parts with a long mold life that can reach up to 500,000 to 1,000,000 shots. The color of the automotive components can also be customized to meet the customer’s needs.

Automotive injection molding is used for a wide range of applications in the automotive industry. It is often used for making automotive body parts, such as bumpers, side skirts, and grilles. It is also used for making engine components, such as air filters, fuel injectors, and spark plugs. In addition, automotive injection molding is also used for making interior components, such as dashboards, door panels, and window regulators.

Injection molding is a reliable and efficient process that can produce automotive components with a high level of precision and consistency. It is often used for mass production, as it can produce a large number of components with a short lead time. Automotive injection molding is also cost-effective, as it eliminates the need for secondary operations and reduces material waste.

Automotive injection molding is an essential process for producing high-quality automotive components that meet the customer’s needs. With its precision, consistency, and cost-effectiveness, it is an ideal solution for the automotive industry.

Customization:

- Mold Life: 500,000-1,000,000 Shots

- Color: Customized

- Lead Time: 15-30 Days

- Molding Type: Injection Molding

- Surface Finish: Smooth

Support and Services:

We provide our customers with comprehensive technical support and service for automotive injection molding. We offer innovative and best-in-class solutions that help our customers to achieve their objectives.

Our technical support staff are experienced in both injection molding and automotive industry. We provide on-site support for setting up and running molding operations, and our team of experts can help customers to optimize their process parameters, troubleshoot any molding issues, and resolve any other technical challenges that may arise.

In addition, we offer comprehensive preventive maintenance services to ensure that the molding equipment is operating at peak performance. We also provide comprehensive training and education programs for our customers, to ensure that they are able to make the most of the equipment and maximize their production efficiency.

We are committed to providing our customers with the best technical support and service for injection molding, and are always available to answer any questions they may have.

Packing and Shipping:

Automotive Injection Molding Packaging and Shipping:

- Packaging: The products are packed in wooden boxes, bubble bags, and foam linings.

- Shipping: The products are shipped via air, sea, and land.

FAQ:

- Q: What is Automotive Injection Molding?

A: Automotive Injection Molding is a process of forming plastics and metals into parts and components for automobiles and other vehicles. - Q: What materials can be used for Automotive Injection Molding?

A: Automotive Injection Molding can be used to form a variety of materials, including thermoplastics, thermosets, and elastomers. - Q: What are the benefits of Automotive Injection Molding?

A: Automotive Injection Molding offers many benefits, including low cost, high accuracy, and fast production rates. - Q: What types of automotive parts can be produced with Automotive Injection Molding?

A: Automotive Injection Molding can be used to produce a variety of parts and components, including engine blocks, intake manifolds, body panels, trim, and lighting systems. - Q: What types of automotive Injection Molding machines are available?

A: There are a variety of Automotive Injection Molding machines available, including horizontal, vertical, and multi-axis machines.